Transitioning from reactive to predictive analytics is akin to moving from relying on a rearview mirror to employing a sophisticated GPS navigation system. When operating in a reactive mode, manufacturers focus solely on past performance, essentially driving while looking in the rearview mirror. In contrast, establishing a predictive analytics framework equips organizations with forward-looking insights, akin to a GPS that not only pinpoints your current location but also warns you of potential traffic jams and hazards miles ahead. This empowering foresight enables manufacturers to adjust their routes before encountering disruptive obstacles, thereby optimizing their operations.

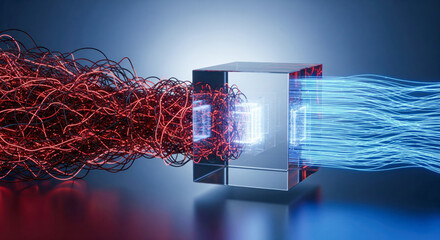

To effectively shift from a reactive to a predictive state, manufacturers must break free from fragmented legacy systems and embrace unified, scalable data architectures that treat data as a vital strategic asset. This transformative journey requires a significant departure from traditional Business Intelligence (BI) approaches, which often report only on what has occurred in the past, toward the adoption of AI-powered models that offer valuable foresight.

Here are the essential steps to facilitate this key transition:

- Establish a Foundational “Data House”

The effectiveness of predictive algorithms is directly linked to the quality of the data they utilize. Therefore, manufacturers need to “get their data house in order” by ensuring impeccable data hygiene and implementing Master Data Management (MDM) practices. This foundational step involves creating a “single source of truth” by consolidating disparate records from various systems—such as Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Customer Relationship Management (CRM)—into a single, centralized platform that fosters consistency and reliability.

- Modernize Infrastructure with Unified Architectures

Achieving predictive analytics capacity requires dismantling data silos that enclose information in incompatible formats, preventing comprehensive analysis. Manufacturers should invest in robust cloud data platforms—such as Microsoft Fabric—and adopt unified data architectures that enable real-time integration and enhanced analytical capabilities. This modern infrastructure transforms the organization’s analytics from simple descriptive dashboards to dynamic, predictive interfaces that will allow agile, real-time decision-making.

- Implement Data Governance and Automation

Successful predictive analytics depends on structured data governance frameworks that define roles and responsibilities, ensuring that data remains trustworthy and easily accessible. Moreover, manufacturers should automate core processes—such as supplier onboarding and risk assessments—to bolster efficiency. This strategic automation not only keeps the underlying data accurate and up to date but also frees up valuable time for employees to focus on high-impact initiatives rather than tedious manual data entry.

- Close the Data Literacy and Skills Gap

A vibrant predictive analytics culture cannot thrive if employees lack the skills to interpret complex insights. Organizations must prioritize targeted training programs designed to enhance data literacy across all levels of the workforce. By empowering employees to transition from reliance on intuition and improvised solutions—often termed “firefighting”—to informed, data-led decision-making, companies can foster a more proactive, insightful operational environment. Currently, 99% of manufacturers surveyed are actively upskilling or reskilling their teams to leverage these advanced technological tools.

- Leverage AI and Third-Party Enrichment

To bolster the accuracy and reliability of predictive models, manufacturers should enrich their internal data by cross-referencing it with third-party reference datasets. This approach standardizes and enhances insights derived from internal data. Once a solid data foundation has been established, organizations can integrate AI and machine learning (ML) models designed for specific applications, such as:

– Predictive Maintenance: Reducing unexpected downtime by 15-25%, thereby optimizing operational efficiency and minimizing disruptions.

– Demand Forecasting: Cutting forecasting errors by up to 50%, which allows for improved inventory management and customer satisfaction.

– Anomaly Detection: Identifying potential production issues before they escalate into costly scrap or delays, ensuring smoother operations and better resource allocation.

- Seek External Validation

Given the daunting technical complexities associated with AI and predictive analytics, many leaders turn to analyst-led guidance to validate and refine their strategic roadmaps. Seeking external expertise helps align internal stakeholders and build consensus around the predictive analytics strategy. By using diagnostics and benchmarking tools, organizations can identify functional gaps in their current operations and measure their progress toward enhanced predictive capabilities, ensuring they remain competitive in an ever-evolving market landscape.